Introduction

The Food and Beverage (F&B) industry is one of the most dynamic and fast-paced sectors, driven by changing consumer preferences, strict quality standards, and complex supply chains. To stay competitive, manufacturers need a system that unifies production, inventory, sales, quality, compliance, and finance all under one platform. This is where ERP Software for the Food and Beverage Industry plays a critical role.

An ERP for Food and Beverage Industry helps streamline operations, reduce waste, improve traceability, and ensure compliance with food safety regulations. By integrating every business process, it enables manufacturers to make data-driven decisions and respond quickly to market demands.

In this blog, we’ll explore how to choose the best ERP software for your food and beverage business, the key features to look for, and why Matiyas Solutions is your trusted technology partner in implementing the right ERP system.

Understanding ERP for the Food and Beverage Industry

ERP for Food and Beverage refers to specialized enterprise resource planning software designed to meet the unique operational challenges of food and beverage manufacturers. Unlike generic ERP systems, Food ERP Software provides functionalities tailored for recipe management, batch tracking, expiration date monitoring, quality control, and regulatory compliance.

The ERP Software for Food Industry integrates departments like production, procurement, inventory, sales, accounting, and distribution. This centralization allows management to have complete visibility of the business from raw material sourcing to product delivery.

Whether you produce packaged foods, dairy, beverages, or frozen goods, the right ERP Software for Food Manufacturing helps automate processes, maintain consistency, and ensure profitability.

Key Challenges in the Food and Beverage Industry

Before selecting an ERP, it’s essential to understand the common challenges faced by food and beverage businesses:

Short Shelf Life: Managing inventory for perishable products requires precise demand forecasting and real-time tracking.

Regulatory Compliance: The industry must follow food safety and labeling standards such as FSSAI, HACCP, or ISO.

Quality Control: Maintaining consistent quality across batches is crucial to brand reputation.

Traceability: Businesses must trace ingredients from suppliers to consumers to ensure safety and recall management.

Fluctuating Demand: Changing customer preferences and seasonal trends demand flexible production planning.

High Operational Costs: Manual systems often lead to inefficiencies and wastage.

An advanced ERP Software for Food and Beverage Industry helps overcome these challenges by providing automation, accuracy, and visibility across all business operations.

Why Implement ERP Software for Food and Beverage Industry

1. Streamlined Production Management

With ERP for Food and Beverage, manufacturers can automate production schedules, track batch progress, and manage resources effectively. It ensures optimal utilization of raw materials, reduces downtime, and maintains consistency.

2. Improved Quality and Safety

ERP systems integrate quality control checkpoints throughout the production cycle. This ensures every product meets the required standards before it reaches the market.

3. Enhanced Traceability

A food beverage ERP software allows tracking of raw materials, ingredients, and final products through lot and batch numbers. In case of a recall, businesses can quickly identify affected items and minimize damage.

4. Real-Time Inventory Management

By maintaining accurate stock data, ERP Software for Food Manufacturing helps manage perishable items, track expiration dates, and avoid overstocking or shortages.

5. Compliance Management

Automated compliance tracking helps businesses adhere to local and international food safety laws. Documentation and audit reports can be generated effortlessly.

6. Better Demand Forecasting

With built-in analytics, ERP systems provide insights into market trends, helping businesses plan production and procurement accordingly.

7. Cost Reduction

Automating manual processes reduces human errors, resource wastage, and administrative costs. Over time, the ROI from implementing a Manufacturing ERP software is substantial.

Key Features to Look for in ERP for Food and Beverage Industry

When choosing an ERP for Food Industry, ensure it includes the following core features:

1. Recipe and Formula Management

Essential for maintaining consistency and controlling ingredient costs. The ERP should handle complex recipes, scaling, and substitutions efficiently.

2. Batch and Lot Tracking

Helps trace every ingredient and product through the entire supply chain for transparency and safety.

3. Quality Control

Built-in QC modules help inspect and verify the quality of raw materials, semi-finished, and finished goods.

4. Production Planning and Scheduling

Advanced planning tools ensure timely production while optimizing resources and minimizing waste.

5. Inventory and Warehouse Management

Automates stock tracking, expiration date management, and warehouse movement with barcode or RFID support.

6. Compliance and Reporting

Generates detailed reports for FSSAI, FDA, ISO, or HACCP compliance, and assists in quick audits.

7. Supply Chain Management

Tracks supplier performance, purchase orders, and logistics in real time for better coordination.

8. Financial Management

Integrates accounting, costing, and profitability analysis to provide a clear financial picture of operations.

9. Sales and Distribution

Manages customer orders, pricing, invoicing, and dispatch to ensure timely delivery and customer satisfaction.

10. Analytics and Dashboards

Provides real-time insights into production, sales, and finances to support data-driven decision-making.

How ERP Software for Food Manufacturing Boosts Productivity

The best ERP Software for Food Manufacturing not only streamlines processes but also empowers teams to make smarter decisions.

Automates repetitive tasks, reducing manual intervention.

Minimizes production errors through accurate recipe and batch control.

Improves collaboration among departments with shared data access.

Ensures transparency across the entire food supply chain.

Enhances customer satisfaction with on-time delivery and consistent quality.

By connecting all departments from procurement to sales ERP becomes the backbone of efficient food manufacturing operations.

ERP for Beverage Industry: Addressing Unique Requirements

The beverage segment, including soft drinks, juices, and alcoholic beverages, faces distinct challenges like managing large batch volumes, flavor variations, and government regulations.

A dedicated ERP for Beverage Industry ensures:

Batch consistency in flavor and formulation.

Accurate bottling and packaging management.

Real-time monitoring of filling lines and production equipment.

Excise and tax compliance tracking for alcoholic beverages.

Demand forecasting for seasonal and promotional sales.

An intelligent food beverage ERP software handles these functions seamlessly, ensuring smooth production and timely delivery.

How to Choose the Right ERP for Your Food and Beverage Business

Selecting the perfect ERP Software for Food and Beverage Industry requires a strategic approach. Here are key factors to consider:

1. Industry-Specific Capabilities

Choose an ERP that caters specifically to Food Manufacturing and Beverage Production, rather than a generic system. Look for recipe management, traceability, and compliance modules.

2. Scalability

Ensure the system can grow with your business from small production units to multi-location operations.

3. Cloud vs. On-Premise

Cloud-based ERP offers flexibility, remote access, and lower IT maintenance. It’s ideal for modern food manufacturers seeking real-time visibility.

4. Integration

The ERP should integrate easily with other tools like CRM, eCommerce platforms, or IoT-based manufacturing devices.

5. User-Friendliness

A simple interface ensures faster adoption by staff and reduces training time.

6. Vendor Support

Partner with a vendor who understands the food industry’s unique needs and offers continuous technical support.

7. Cost and ROI

Consider the total cost of ownership and long-term benefits rather than just upfront pricing.

Why Choose Matiyas Solutions for Food and Beverage ERP

Matiyas Solutions offers a cutting-edge ERP Software for Food and Beverage Industry, designed to simplify operations, enhance compliance, and improve profitability.

Here’s why leading manufacturers trust Matiyas ERP:

1. Industry Expertise

With deep knowledge of Food Manufacturing and Beverage Production, Matiyas ERP is customized to address your specific pain points.

2. Comprehensive Modules

From procurement and inventory to production and finance, all operations are unified in one centralized system.

3. Real-Time Analytics

Get actionable insights into production performance, wastage, and profitability.

4. Cloud-Enabled Flexibility

Access your ERP anytime, anywhere ideal for growing and multi-location food businesses.

5. Seamless Integration

Integrates effortlessly with POS, CRM, and third-party applications.

6. Regulatory Compliance

Stay audit-ready with automated reporting and complete traceability from farm to fork.

7. Dedicated Support

Matiyas Solutions provides continuous assistance and training to ensure a smooth ERP implementation journey.

Conclusion

The food and beverage industry is evolving rapidly, driven by technology, consumer trends, and strict compliance standards. To thrive in this environment, businesses need more than traditional management tools they need an intelligent, integrated, and scalable ERP system.

By implementing ERP Software for Food Industry, companies can automate operations, improve traceability, maintain quality, and boost profitability.

Matiyas Solutions offers the most reliable and advanced ERP for Food and Beverage Industry, empowering manufacturers to transform their business digitally and achieve long-term success.

If you’re ready to optimize your food manufacturing or beverage production process with cutting-edge ERP software, contact Matiyas Solutions today and take the first step toward smarter, more efficient operations.

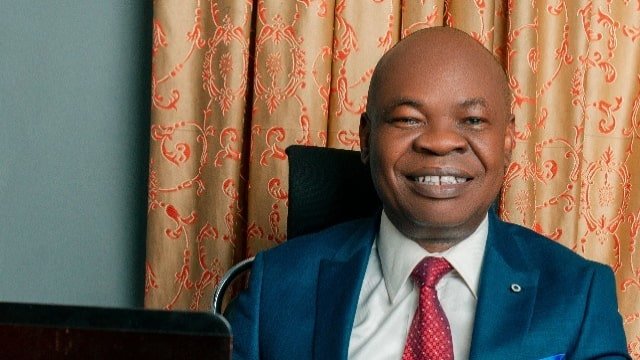

"I am quite happy with the ERP solution provided by Matiyas. Before we implemented their system, our organization was struggling with inefficient processes and fragmented data. Their customized ERP solution not only streamlined our workflows but also provided real-time insights into our operations. The customer support from Matiya's Team has been exceptional throughout the journey."

"I am quite happy with the ERP solution provided by Matiyas. Before we implemented their system, our organization was struggling with inefficient processes and fragmented data. Their customized ERP solution not only streamlined our workflows but also provided real-time insights into our operations. The customer support from Matiya's Team has been exceptional throughout the journey."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"I wanted to thank you Matiyas team to set-up the ERP system based on our business process. The assistance was invaluable in helping my company get as we requested. We sincerely appreciate your efforts and thanks again Matiyas team to provide us a best solution with the erp system."

"I wanted to thank you Matiyas team to set-up the ERP system based on our business process. The assistance was invaluable in helping my company get as we requested. We sincerely appreciate your efforts and thanks again Matiyas team to provide us a best solution with the erp system." "Go ahead with Matiyas and Capture data at lowest level and you can build | report | analyse | get insights across business dimension to take informed decisions."

"Go ahead with Matiyas and Capture data at lowest level and you can build | report | analyse | get insights across business dimension to take informed decisions."

"The implementation of the Matiyas ERP solution has revolutionized our workflow. The automation of previously manual processes has not only saved us time but also significantly reduced errors. It’s like having an extra set of hands on our team, streamlining operations and boosting productivity"

"The implementation of the Matiyas ERP solution has revolutionized our workflow. The automation of previously manual processes has not only saved us time but also significantly reduced errors. It’s like having an extra set of hands on our team, streamlining operations and boosting productivity"

"We would definitely encourage anyone willing to get services from Matiyas. they are honest hardworking and smart team. they stretch them maximum to achieve success for their clients."

"We would definitely encourage anyone willing to get services from Matiyas. they are honest hardworking and smart team. they stretch them maximum to achieve success for their clients."

"Matiyas system has been helpful to us for execution of our day-to-day operations in scholarship. The team has been very supportive and always available to accommodate with any challenges that we have faced. Overall, we had good experience working with Matiyas!"

"Matiyas system has been helpful to us for execution of our day-to-day operations in scholarship. The team has been very supportive and always available to accommodate with any challenges that we have faced. Overall, we had good experience working with Matiyas!"

"We at I2E Consulting were looking for Healthcare Module consultation in ERPNext and we came across Matiyas Solutions website. From managing the business to adding his Expertise in Healthcare module, Hasan has done it all single handedly. All our Queries were solved in a timely manner. Regular follow ups were done."

"We at I2E Consulting were looking for Healthcare Module consultation in ERPNext and we came across Matiyas Solutions website. From managing the business to adding his Expertise in Healthcare module, Hasan has done it all single handedly. All our Queries were solved in a timely manner. Regular follow ups were done."

"Our company is very new to ERP, we tried to implement ERP by ourselves, however along the way we found struggles as we are very new. We are lucky HasanAli from Matiyas helped us in many ways, from a simple question to very complex developments and deployments. Rates are reasonable too! We are happy that Matiyas is there to help us."

"Our company is very new to ERP, we tried to implement ERP by ourselves, however along the way we found struggles as we are very new. We are lucky HasanAli from Matiyas helped us in many ways, from a simple question to very complex developments and deployments. Rates are reasonable too! We are happy that Matiyas is there to help us."

"The folks at Matiyas Software are the best. They're skilled, work quickly and professionally, and were able to tailor ERP to our exact specifications. Would use them again."

"The folks at Matiyas Software are the best. They're skilled, work quickly and professionally, and were able to tailor ERP to our exact specifications. Would use them again."

"Very knowledgeable and prompt and professional. I highly recommend Matiyas for any ERP customizations."

"Very knowledgeable and prompt and professional. I highly recommend Matiyas for any ERP customizations."