The food and beverage industry is undergoing a major transformation driven by increasing consumer expectations, regulatory demands, sustainability goals, and a competitive global marketplace. As this sector evolves, businesses must adopt smarter, more efficient, and scalable systems to stay ahead. ERP integration, particularly through powerful platforms like ERPNext software, is becoming the backbone of modern operations in the food and beverage manufacturing industry.

In this blog, we explore how ERP software for food and beverage industry is shaping the future, improving productivity, ensuring compliance, and enabling digital transformation in food industry operations.

Introduction: The Changing Landscape of Food and Beverage Manufacturing

The food and beverage industry is among the most dynamic sectors worldwide. It must continually adapt to changing tastes, health concerns, dietary trends, stringent food safety regulations, and environmental sustainability requirements. Amidst these challenges, Digital Transformation in Manufacturing is no longer optional it’s essential.

Traditional systems and manual processes are no longer sufficient to ensure end-to-end traceability, optimized inventory management, or quick response to market changes. That’s where a robust ERP solution like ERPNext Food Software comes into play.

Why ERP Integration is Crucial for Food and Beverage Businesses

1. End-to-End Supply Chain Visibility

ERP for Food and Beverage provides full visibility into every aspect of the supply chain from procurement and production to packaging and distribution. This real-time transparency is critical for tracking ingredients, monitoring batch quality, and ensuring on-time delivery.

2. Improved Traceability and Compliance

Regulatory bodies demand detailed records for audits, product recalls, and labeling. ERP Software for food industry helps maintain compliance with local and international food safety standards by enabling traceability of every ingredient and process step.

3. Minimized Waste and Inventory Loss

Spoilage, overproduction, and mismanaged stock lead to significant losses. ERP for Food and beverage manufacturing industry optimizes inventory levels and automates expiration tracking, reducing waste and improving profitability.

4. Enhanced Recipe and Batch Management

Precise recipe management is at the heart of quality in food manufacturing. ERPNext allows food companies to define and control multi-level recipes and manage batch-wise production efficiently.

The Role of ERPNext in the Future of Food & Beverage Industry

ERPNext Software is a modern, open-source ERP solution that supports the unique needs of the food and beverage ERP software segment. Its modular, flexible design allows food businesses to scale, automate, and integrate operations across the board.

Key Features of ERPNext for Food & Beverage Businesses

1. Recipe and Batch Management

Define, control, and manage multi-level recipes with accurate ingredient tracking and batch-wise production control.

2. Inventory and Expiry Management

Track raw materials, finished goods, and monitor expiry dates to reduce waste and ensure product freshness.

3. Quality Control

Set quality checks at every stage of production to meet safety standards and maintain product consistency.

4. Production Planning

Plan and schedule production based on real-time demand, raw material availability, and machine capacity.

5. Traceability and Compliance

Maintain complete traceability of ingredients and processes to meet food safety regulations like FSSAI, HACCP, and ISO.

6. Sales and Order Management

Manage B2B and B2C orders, pricing, and dispatch with real-time order tracking and automated billing.

7. Warehouse Management

Optimize space, automate stock movements, and enable faster pick-pack-ship processes.

8. Supplier and Purchase Management

Track vendor performance, manage purchase cycles, and automate reordering for essential ingredients.

9. Accounting and Cost Control

Manage finances, control food production costs, and generate real-time profit reports from a single dashboard.

10. Multi-Location and Multi-Company Support

Operate and manage multiple factories, warehouses, and brands within a single ERP system.

Benefits of ERPNext for Food Manufacturing Companies

1. Improved Production Efficiency

Automate processes and streamline workflows to reduce delays, minimize errors, and boost overall productivity.

2. Better Inventory Control

Track stock levels, manage raw materials, and reduce wastage by ensuring the right ingredients are available when needed.

3. Accurate Batch and Recipe Management

Maintain consistent product quality by managing recipes and batches with precision and full traceability.

4. Regulatory Compliance Made Easy

Stay compliant with food safety standards like FSSAI, HACCP, and ISO through automated documentation and audit trails.

5. Real-Time Visibility Across Operations

Get instant access to data on production, sales, inventory, and finance to make faster, informed decisions.

6. Reduced Operational Costs

Cut down on manual tasks, excess inventory, and production inefficiencies to save time and money.

7. Enhanced Quality Assurance

Set up quality checks at every stage of the production process to ensure high standards are always met.

8. Faster Order Fulfillment

Process customer orders more quickly and accurately with automated sales and dispatch tracking.

9. Scalability for Growth

Easily add new products, locations, or business units as your company grows without changing systems.

10. Better Customer Satisfaction

Deliver consistent, high-quality products on time, which helps build trust and long-term customer relationships.

Digital Transformation in Food Industry: Why It Matters

The digital transformation in food industry is more than a tech trend it’s about reimagining how food businesses operate. Cloud-based ERP systems like ERPNext empower companies to:

Shift to data-driven strategies

Integrate operations across departments

Embrace sustainable practices

Innovate faster with scalable technology

From smart factories to AI-assisted demand forecasting, digital transformation in manufacturing is reshaping how the food industry meets the needs of a fast-paced world.

ERP Software for Food Manufacturing: Key Future Trends

As we look forward, several trends will drive innovation in ERP software for food and beverage industry:

1. Cloud-Based ERP Adoption

More food manufacturers are shifting to cloud-based ERP systems for real-time access, lower IT costs, and remote operations management.

2. Mobile ERP Access

With mobile-friendly ERP interfaces, decision-makers can manage inventory, production, and approvals on the go.

3. Integrated Traceability and Compliance Tools

ERP systems will increasingly include built-in modules to meet evolving food safety standards and trace ingredients end-to-end.

4. Smart Inventory Management

Advanced ERP software will use automated reordering, real-time stock updates, and expiry tracking to reduce waste and manage shelf life better.

5. Customization for Specialized Food Processes

ERP platforms will offer more industry-specific features to support unique needs like recipe scaling, allergen tracking, and packaging requirements.

6. Better Demand Forecasting

ERP systems will help food businesses forecast demand more accurately by analyzing sales history, seasonal trends, and customer behavior.

7. Sustainability Tracking

Modern ERP solutions will support sustainability goals by tracking resource usage, waste, energy consumption, and carbon footprint.

8. Enhanced Supplier Collaboration

ERP platforms will enable better coordination with suppliers, helping manage contracts, deliveries, and quality standards more efficiently.

9. Faster Implementation and User-Friendly Interfaces

Future ERP solutions will focus on quicker deployments and simple, intuitive dashboards for better user adoption.

10. Integration with IoT and Smart Devices

ERP software will connect with sensors, scales, and equipment on the production floor to monitor real-time data and improve process control.

ERP for Food Processing Industry: The Competitive Edge

In the ERP for Food Processing Industry, success depends on how well a business can standardize and scale production. ERPNext offers:

Centralized control over plant operations

Seamless integration with weighing scales, barcode scanners, and shop floor devices

Complete visibility of material consumption, yield, and scrap

Support for multi-stage production workflows and custom processing requirements

Whether it’s a dairy unit, a confectionery plant, or a frozen foods supplier, ERP Software for Food Manufacturing ensures regulatory alignment, faster batch processing, and data-driven decisions.

ERP Software for Food Industry: Why Choose Matiyas Solutions

Implementing ERP for food industry isn’t just about software it’s about understanding the sector’s complexity. At Matiyas Solutions, we specialize in customizing ERPNext software to meet the specific needs of food processors, distributors, and manufacturers.

Our Strengths:

8 Years of experience in food manufacturing ERP implementations

Deep industry knowledge of compliance, recipes, shelf-life tracking, and quality assurance

Proven success in delivering ROI-focused ERP transformations

End-to-end support from consultation to deployment and training

Final Thoughts: Embrace the Future with ERPNext

The future of the food and beverage industry is digital, agile, and customer-centric. To compete in this fast-paced environment, companies must move beyond spreadsheets and outdated software. A future-ready solution like ERPNext software, customized and implemented by Matiyas Solutions, ensures operational excellence, compliance, and sustained growth.

Whether you’re a startup producing organic foods or a large-scale beverage distributor, investing in ERP software for food and beverage industry is no longer a luxury it’s a necessity. It’s time to embrace ERP Software for Food Manufacturing and join the digital revolution in food production.

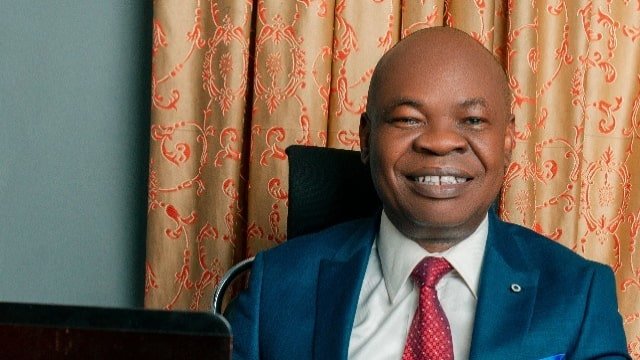

"I am quite happy with the ERP solution provided by Matiyas. Before we implemented their system, our organization was struggling with inefficient processes and fragmented data. Their customized ERP solution not only streamlined our workflows but also provided real-time insights into our operations. The customer support from Matiya's Team has been exceptional throughout the journey."

"I am quite happy with the ERP solution provided by Matiyas. Before we implemented their system, our organization was struggling with inefficient processes and fragmented data. Their customized ERP solution not only streamlined our workflows but also provided real-time insights into our operations. The customer support from Matiya's Team has been exceptional throughout the journey."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"I wanted to thank you Matiyas team to set-up the ERP system based on our business process. The assistance was invaluable in helping my company get as we requested. We sincerely appreciate your efforts and thanks again Matiyas team to provide us a best solution with the erp system."

"I wanted to thank you Matiyas team to set-up the ERP system based on our business process. The assistance was invaluable in helping my company get as we requested. We sincerely appreciate your efforts and thanks again Matiyas team to provide us a best solution with the erp system." "Go ahead with Matiyas and Capture data at lowest level and you can build | report | analyse | get insights across business dimension to take informed decisions."

"Go ahead with Matiyas and Capture data at lowest level and you can build | report | analyse | get insights across business dimension to take informed decisions."

"The implementation of the Matiyas ERP solution has revolutionized our workflow. The automation of previously manual processes has not only saved us time but also significantly reduced errors. It’s like having an extra set of hands on our team, streamlining operations and boosting productivity"

"The implementation of the Matiyas ERP solution has revolutionized our workflow. The automation of previously manual processes has not only saved us time but also significantly reduced errors. It’s like having an extra set of hands on our team, streamlining operations and boosting productivity"

"We would definitely encourage anyone willing to get services from Matiyas. they are honest hardworking and smart team. they stretch them maximum to achieve success for their clients."

"We would definitely encourage anyone willing to get services from Matiyas. they are honest hardworking and smart team. they stretch them maximum to achieve success for their clients."

"Matiyas system has been helpful to us for execution of our day-to-day operations in scholarship. The team has been very supportive and always available to accommodate with any challenges that we have faced. Overall, we had good experience working with Matiyas!"

"Matiyas system has been helpful to us for execution of our day-to-day operations in scholarship. The team has been very supportive and always available to accommodate with any challenges that we have faced. Overall, we had good experience working with Matiyas!"

"We at I2E Consulting were looking for Healthcare Module consultation in ERPNext and we came across Matiyas Solutions website. From managing the business to adding his Expertise in Healthcare module, Hasan has done it all single handedly. All our Queries were solved in a timely manner. Regular follow ups were done."

"We at I2E Consulting were looking for Healthcare Module consultation in ERPNext and we came across Matiyas Solutions website. From managing the business to adding his Expertise in Healthcare module, Hasan has done it all single handedly. All our Queries were solved in a timely manner. Regular follow ups were done."

"Our company is very new to ERP, we tried to implement ERP by ourselves, however along the way we found struggles as we are very new. We are lucky HasanAli from Matiyas helped us in many ways, from a simple question to very complex developments and deployments. Rates are reasonable too! We are happy that Matiyas is there to help us."

"Our company is very new to ERP, we tried to implement ERP by ourselves, however along the way we found struggles as we are very new. We are lucky HasanAli from Matiyas helped us in many ways, from a simple question to very complex developments and deployments. Rates are reasonable too! We are happy that Matiyas is there to help us."

"The folks at Matiyas Software are the best. They're skilled, work quickly and professionally, and were able to tailor ERP to our exact specifications. Would use them again."

"The folks at Matiyas Software are the best. They're skilled, work quickly and professionally, and were able to tailor ERP to our exact specifications. Would use them again."

"Very knowledgeable and prompt and professional. I highly recommend Matiyas for any ERP customizations."

"Very knowledgeable and prompt and professional. I highly recommend Matiyas for any ERP customizations."