Wunderkraf Paperware, a key player in the paper manufacturing industry, was struggling with process inefficiencies, inadequate inventory control, and disjointed operations across departments. Manual order tracking, a lack of real-time insights, and growing compliance requirements further complicated their operations. To resolve these challenges and move towards a scalable, digitally driven future, Wunderkraf partnered with Matiyas Solutions for the implementation of ERPNext, a comprehensive ERP solution tailored to manufacturing industries.

The result? A powerful transformation that streamlined processes, optimised costs, and laid the foundation for smarter, real-time business decisions. This case study explores the challenges faced by Wunderkraf, the ERPNext modules implemented, the impact on operations, and how this digital shift has paved the way for growth and efficiency.

Challenges

Before embracing ERPNext, Wunderkraf Paperware was running its operations through a combination of spreadsheets, manual records, and disconnected software tools. This setup was not only time-consuming but also led to inconsistent data, errors, and poor coordination across departments. The primary challenges included:

- Manual and Inefficient Inventory & Order Tracking

Inventory was tracked manually, leading to stock mismatches, delayed order fulfilment, and customer dissatisfaction. - Lack of Real-Time Production and Sales Insights

Wunderkraf had no visibility into live production status, sales performance, or raw material consumption, making it difficult to plan effectively. - Disconnected Workflows Between Manufacturing, Sales, and Procurement

Departments operated in silos, resulting in frequent miscommunication and delays, particularly in order fulfilment and procurement. - Compliance and Quality Control in Paper Production

Maintaining consistent quality standards and adhering to environmental regulations were becoming increasingly difficult without a centralized system. - High Operational Costs Due to Process Inefficiencies

Redundant manual work, delayed decisions, and lack of automation contributed to rising costs across departments.

These issues signalled the urgent need for an integrated and intelligent solution.

Solutions

To overcome these operational and structural challenges, Wunderkraf partnered with Matiyas Solutions to implement ERPNext for Manufacturing. The solution was designed to unify all key business processes from procurement to production, finance to customer relationship management under a single digital platform.

Key solutions delivered include:

- ERPNext Implementation – Unified Business Management

A centralized system replaced manual tools and disconnected software, covering everything from stock and sales to payroll and compliance. - Process Automation – Reducing Human Errors and Delays

Order processing, inventory management, payroll, and procurement workflows were automated, significantly reducing manual work and minimizing errors. - Real-Time Data and Analytics – Empowering Decision-Making

With ERPNext’s built-in reporting and dashboard capabilities, management gained access to live data on stock levels, production KPIs, sales, and expenses. - Custom Workflows Aligned with Manufacturing Processes

ERPNext was tailored to match Wunderkraf’s unique paper manufacturing operations, including quality control, batch-wise production, and compliance documentation. - Phased Rollout – Ensuring Smooth Transition

The implementation was broken into phases to reduce operational disruption, ensuring each module was adopted with full user readiness. - Comprehensive Employee Training

All key users received role-based training to ensure quick adoption and efficient use of the ERP system across departments.

Impact

The results of implementing ERPNext were both immediate and far-reaching. Wunderkraf experienced significant improvements across their operations:

- Improved Production Planning and Reduced Waste

Real-time insights into production stages enabled better resource allocation and planning, leading to lower wastage and higher throughput. - Enhanced Customer Relationship Management (CRM)

Automated sales workflows, customer tracking, and real-time order updates strengthened client relationships and improved customer satisfaction. - Accurate Stock Tracking

The integrated stock management system ensured precise control of inventory, reducing stockouts and over-purchasing. - Streamlined Procurement and Sales Processes

Integration between purchase, inventory, and sales led to faster order processing, better vendor management, and efficient reordering. - Better Financial Control and Cost Optimization

Real-time financial tracking and cost analysis tools provided management with visibility into cash flows, profitability, and departmental budgets.

Overall, the deployment of ERPNext Software helped Wunderkraf Paperware achieve operational excellence and positioned the company for scalable growth.

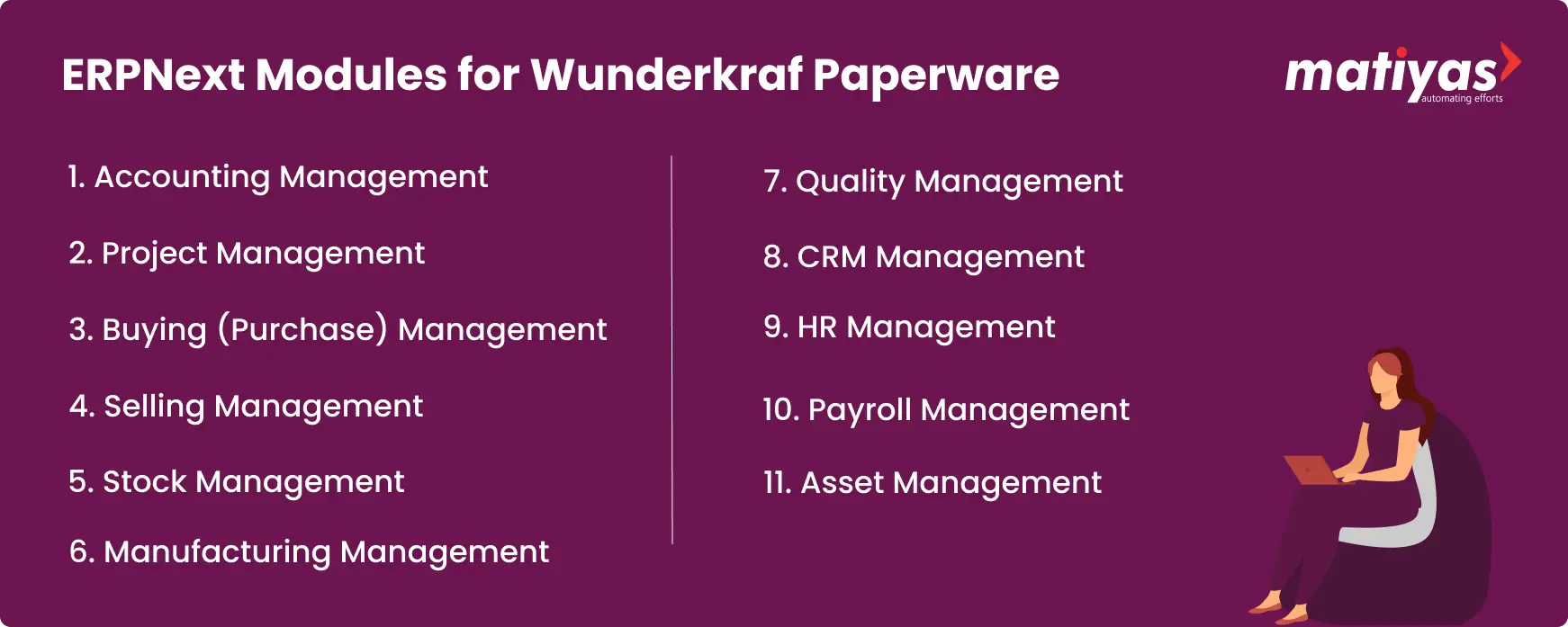

ERPNext Modules for Wunderkraf Paperware

To meet its business needs, Wunderkraf adopted several ERPNext modules that played a vital role in transforming operations:

- Accounting Management

Complete tracking of incomes, expenses, tax compliance, and real-time financial reports enabled tighter financial control. - Project Management

Enabled batch-wise tracking of production orders, delivery timelines, and team responsibilities. - Buying (Purchase) Management

Simplified procurement processes, including vendor management, purchase orders, and inventory replenishment. - Selling Management

Automation of the sales cycle from quotations and sales orders to invoicing and delivery tracking. - Stock Management

Live inventory visibility, automatic reordering, stock audits, and warehouse-level tracking improved inventory accuracy. - Manufacturing Management

Planning and tracking of work orders, raw material consumption, machine capacity, and production timelines. - Quality Management

Quality checks and compliance logs ensured consistent product standards and regulatory adherence. - CRM Management

Managed leads, opportunities, communications, and follow-ups to strengthen customer engagement. - HR Management

Centralised employee records, job assignments, and attendance logs helped streamline HR operations. - Payroll Management

Automated salary calculations, deductions, and payslips ensured accuracy and compliance with labor laws. - Asset Management

Lifecycle tracking of plant and machinery ensured timely maintenance and prevented unplanned downtime.

These modules were configured to suit the paper manufacturing industry, making ERPNext a comprehensive and scalable ERP software for manufacturing.

Testimonial

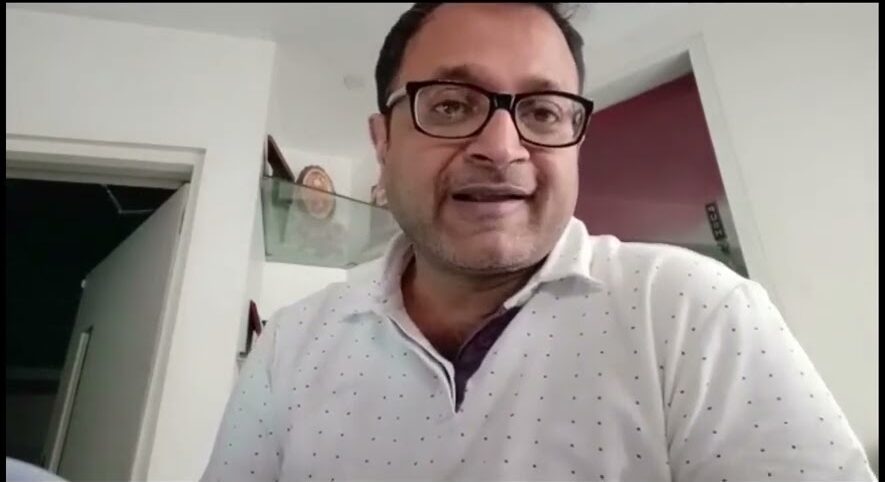

“Implementing ERPNext with the support of Matiyas Solutions has transformed the way we operate. What once took hours of manual coordination across departments now happens seamlessly and in real-time. From production to payroll, every function is more organized, efficient, and transparent. We’ve significantly reduced errors, optimised costs, and improved our response time to customer demands. ERPNext has not only simplified our processes but empowered us to grow with confidence.”

Manoj Gohel, Head of Operations, Wunderkraf Paperware

Conclusion

The successful ERPNext implementation at Wunderkraf Paperware exemplifies how digital transformation in manufacturing can drive real business results. By addressing core challenges and automating processes across departments, the company has significantly improved its operational efficiency, cost control, and customer service.

Matiyas Solutions, with its expertise in ERP software for Manufacturing, delivered a customized ERPNext deployment that fits the unique requirements of the paper manufacturing industry. From real-time inventory management to streamlined financial control, Wunderkraf’s journey stands as a model for other manufacturers seeking sustainable growth through technology.

Whether you’re a small manufacturer or a large-scale enterprise, embracing digital transformation with a robust ERP system like ERPNext can help you stay competitive in today’s dynamic industrial landscape.

"I am quite happy with the ERP solution provided by Matiyas. Before we implemented their system, our organization was struggling with inefficient processes and fragmented data. Their customized ERP solution not only streamlined our workflows but also provided real-time insights into our operations. The customer support from Matiya's Team has been exceptional throughout the journey."

"I am quite happy with the ERP solution provided by Matiyas. Before we implemented their system, our organization was struggling with inefficient processes and fragmented data. Their customized ERP solution not only streamlined our workflows but also provided real-time insights into our operations. The customer support from Matiya's Team has been exceptional throughout the journey."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"Matiyas offered us a functionally strong and automated solution to address the end-to-end needs of our business operation. This solutions will be able to scale and grow our business and it will surely reduce manual interventions."

"I wanted to thank you Matiyas team to set-up the ERP system based on our business process. The assistance was invaluable in helping my company get as we requested. We sincerely appreciate your efforts and thanks again Matiyas team to provide us a best solution with the erp system."

"I wanted to thank you Matiyas team to set-up the ERP system based on our business process. The assistance was invaluable in helping my company get as we requested. We sincerely appreciate your efforts and thanks again Matiyas team to provide us a best solution with the erp system."

"The implementation of the Matiyas ERP solution has revolutionized our workflow. The automation of previously manual processes has not only saved us time but also significantly reduced errors. It’s like having an extra set of hands on our team, streamlining operations and boosting productivity"

"The implementation of the Matiyas ERP solution has revolutionized our workflow. The automation of previously manual processes has not only saved us time but also significantly reduced errors. It’s like having an extra set of hands on our team, streamlining operations and boosting productivity"

"Our company is very new to ERP, we tried to implement ERP by ourselves, however along the way we found struggles as we are very new. We are lucky HasanAli from Matiyas helped us in many ways, from a simple question to very complex developments and deployments. Rates are reasonable too! We are happy that Matiyas is there to help us."

"Our company is very new to ERP, we tried to implement ERP by ourselves, however along the way we found struggles as we are very new. We are lucky HasanAli from Matiyas helped us in many ways, from a simple question to very complex developments and deployments. Rates are reasonable too! We are happy that Matiyas is there to help us."

"The folks at Matiyas Software are the best. They're skilled, work quickly and professionally, and were able to tailor ERP to our exact specifications. Would use them again."

"The folks at Matiyas Software are the best. They're skilled, work quickly and professionally, and were able to tailor ERP to our exact specifications. Would use them again."

"Very knowledgeable and prompt and professional. I highly recommend Matiyas for any ERP customizations."

"Very knowledgeable and prompt and professional. I highly recommend Matiyas for any ERP customizations."